Start accelerating your digital change

Published on 26 Sep 2023 by The Manufacturer

There are a number of methods to enhance performance, boost store flooring versatility and protect information security … all on the marketplace today for makers of lots of sizes.

As makers look for to discover its method into the digital world, the whole procedure chain requires the combination of providers who can react to the requirements of the market. The circumstance has extremely little ‘history’ therefore big end-customers and factory of all sizes are looking for support from their providers, while the device tool contractors are similarly looking for to partner with hardware, software application, interactions and controls providers to bring the most required maker types to market.

Within this situation, the big producers concentrate on the ‘broad view’ as they connect their production departments, typically situated in various cities or perhaps nations throughout the supply chain, while the little agreement producer with a lots regional clients questions how this drive to the digital factory will affect their world– and it will.

Fortunately is they can currently use the IT, apps and interaction gadgets onboard much of today’s sophisticated device tools and the quickly emerging ability of brand-new employees in the device tool market to establish and carry out the 3 fundamental levels of factory operations.

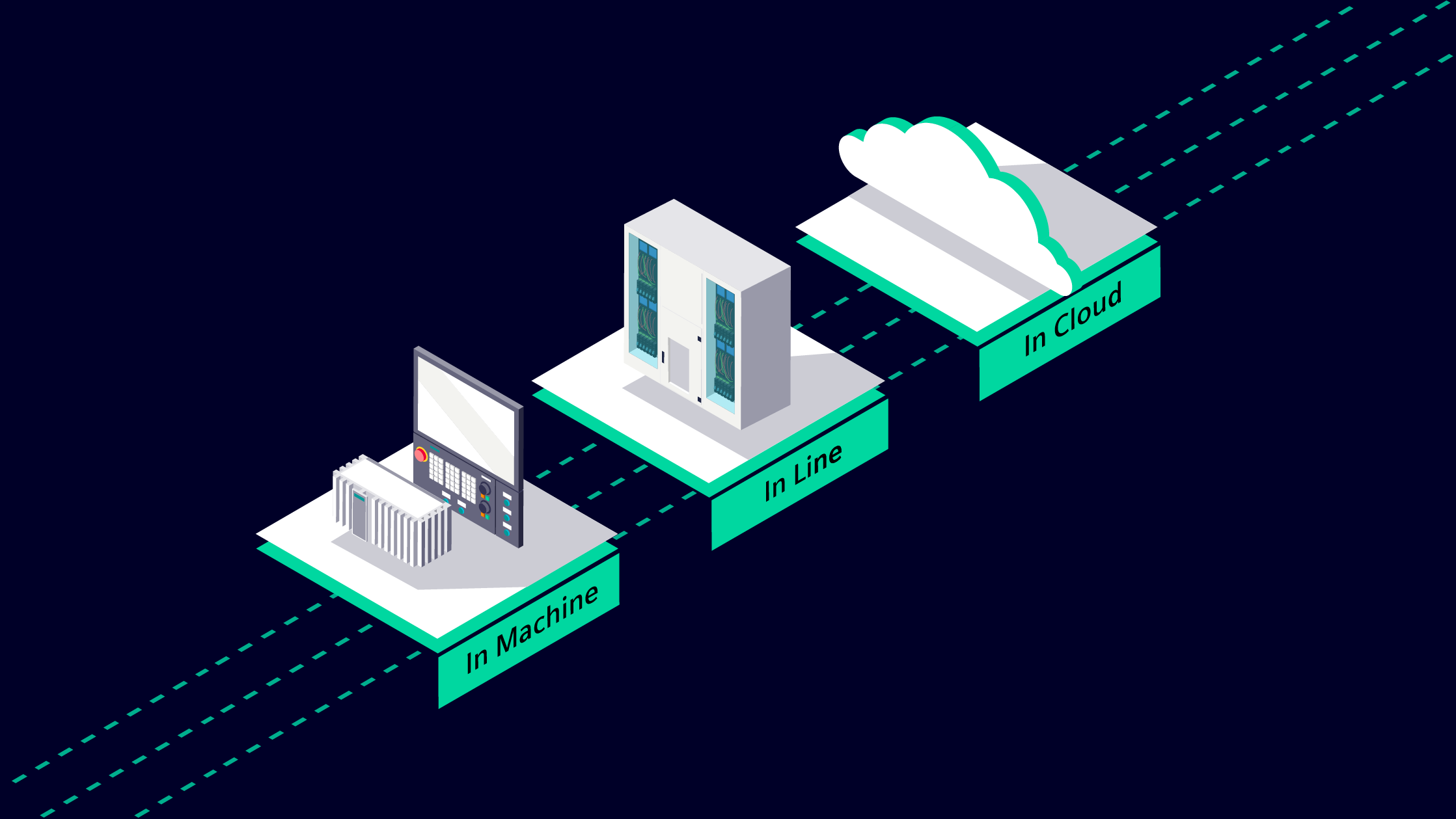

These levels consist of the interactions hardware and procedures at the device, the combination of inline device production and the information homeowner in the cloud, which can be utilized today in lots of methods to enhance efficiency through automated analytics of the store flooring’s utilisation; to improve store flooring versatility through optimised techniques of production; and to maintain information security by cutting edge software application services.

In essence, the capture and control of such information drives the performance of a little store or big production department in rather comparable methods. The idea of your production viewed as an eco-system, with details and control abilities at all levels, can drive that “factory of the future” and, fortunately, it can do so today.

Digitalisation, for instance from Siemens, can be executed at every level of maker operation today

From the CNC on your makers, whether they are number 3 in a mould store or 3 hundred at a transmission plant, you can draw out the pre-analytics that can be utilized to feed existing apps or to establish the most helpful apps to fit your production plan and workflow.

The appeal of the app, whether you produce your own, have a third-party integrator establish it or utilize existing options, is that it offers the hierarchy of details to your operator, line manager, plant operations workers or international IT department in a comparable way.

This scalability uses instant advantage to producers of all sizes and it does so, today. Maker tool users can rapidly and quickly set up a CNC device’s connections and establish its program status and running mode. This will cause increased production performance, dependability and accessibility of the device.

Cloud-based systems constantly raise the concern of security concerns, as the information circulation in genuine time at high-speed and can be made available to lots of levels of info supervisors and operations workers. It is crucial that an extensive evaluation of the access to that information precede the advancement of any interactions procedure.

Digitalisation is not always an expensive endeavor. Actions can be rapidly executed on the store flooring, for example, through the usage of little PCs. For the maker contractor, the engineering advancement of the ‘digital twin’, where a maker is totally created, commissioned and test run in a virtual environment, is quickly altering the playing field in this market.

Secret visual for a location of interest of CNC Shopfloor Management Software– Machine engineering

The variety of linked devices is increasing significantly and this is not merely engineering accessory, it is an essential function for any producer. Having the ability to rapidly figure out the Overall Equipment Effectiveness (OEE) and perform useful, advantageous predictive upkeep actions on your makers will contribute significantly to the production and success of your operation.

The management these days’s production stores and production departments have the obstacle to end up being mindful of all these offered innovations and chart a course for their application. This is not a ‘one day’ situation; it is a crucial journey for stores of all sizes, if they wish to stay competitive in today’s altering market.

My last piece of guidance– take a look at digitalisation as an umbrella for the safe and secure protecting of clever information, not simply huge information. IIOT is the important connection for all the components of information on maker efficiency, products circulation, operations effectiveness and eventually your general efficiency.

The future is now and it’s an interesting time in our company.

About the author

John Meyer, Siemens Industry, Inc.

John Meyer, Siemens Industry, Inc.

To find out more on this post, please contact:

John Meyer, Marketing Communications Manager, Siemens Industry, Inc.

Digital Industries– Motion Control

390 Kent Avenue

Elk Grove Village, IL 60007

+1 847 640 1595